Jinteng mould has more than 20 years of working experience in the filed of “PET packaging’, providing customers with rich experience, professional mold and equipment production, and bottles production.

Jinteng stands out for creativity in the study and complete product development, finding the best compromise between aesthetics and mechanical performance. The industrialization of the product allows our customers to be efficient and competitive.

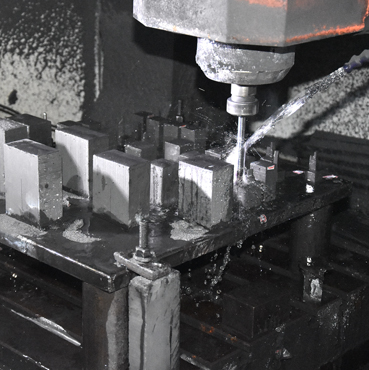

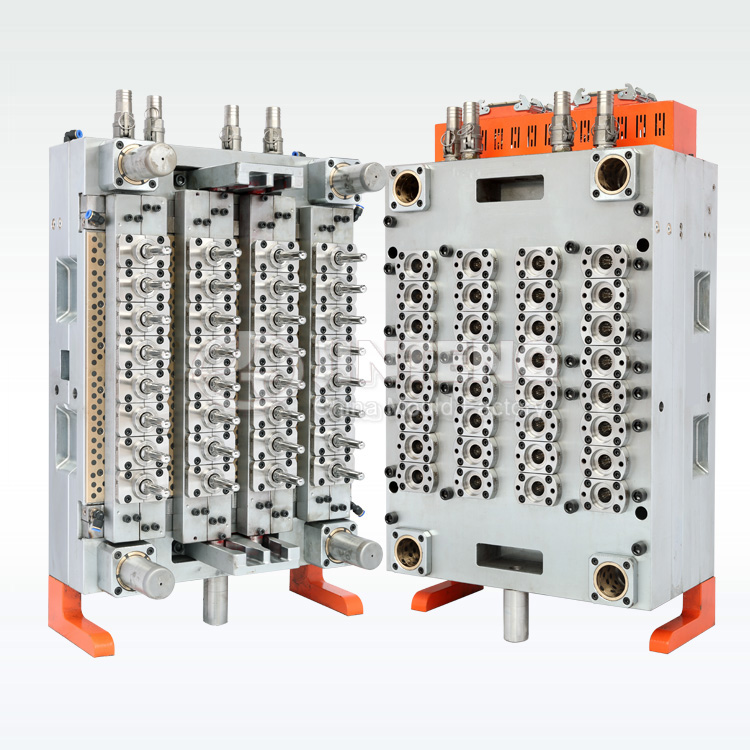

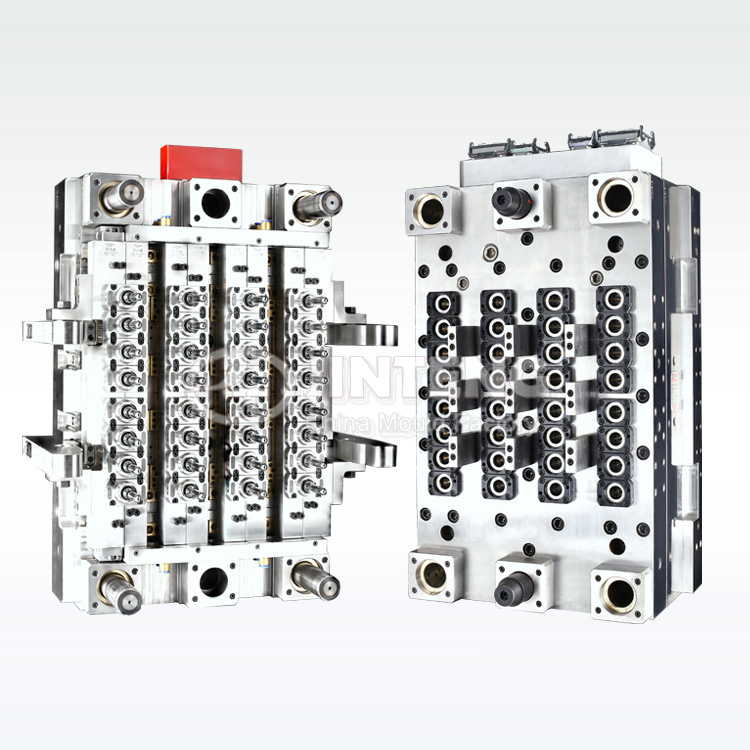

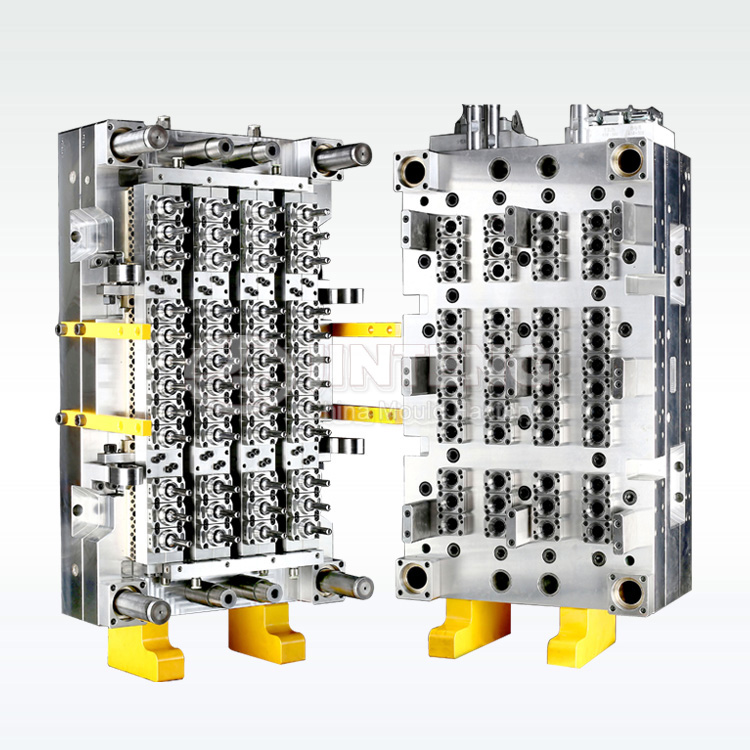

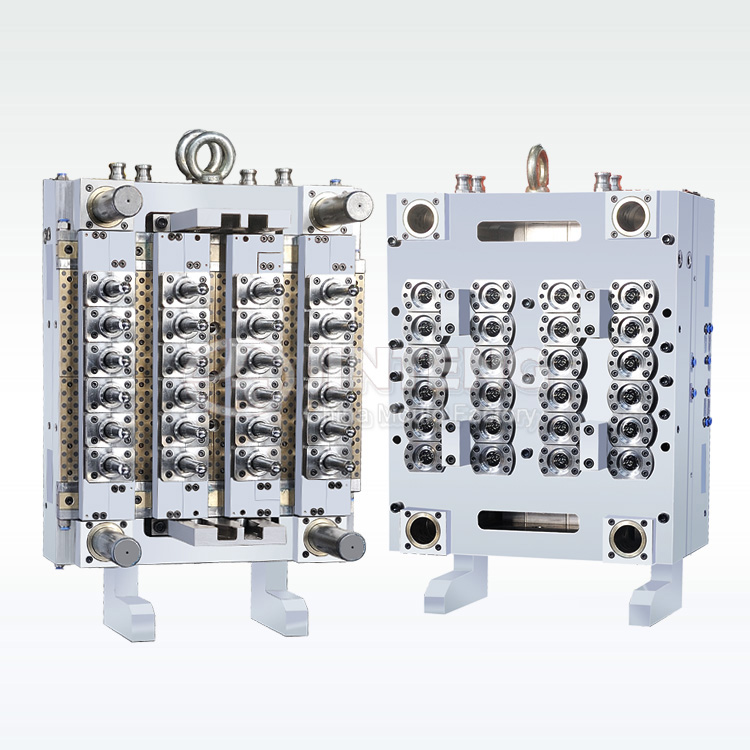

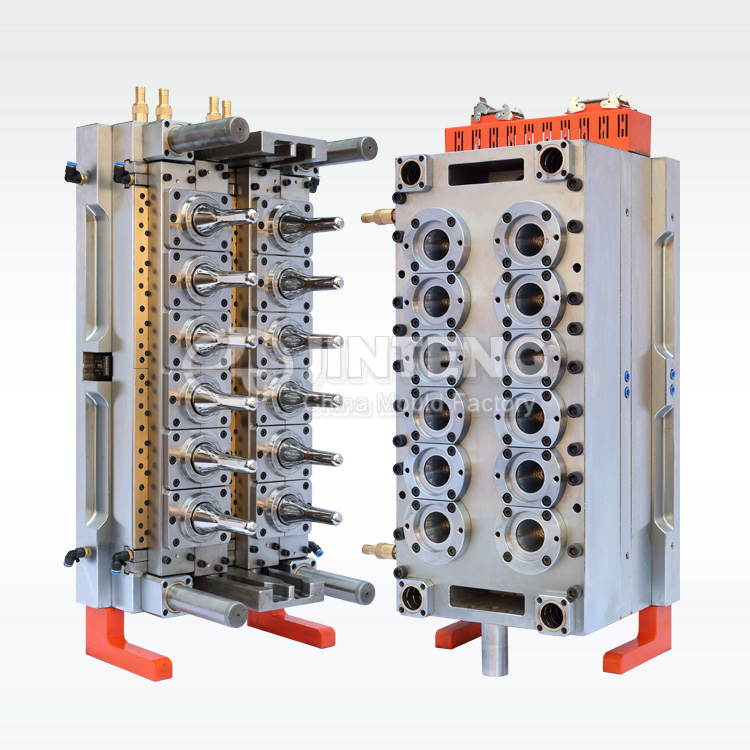

Jinteng Mould has 20 years of technology and production eexperence of PET preform mould. Jinteng has become a world-renowned manufacturer of PET preform mould. It produces more than 100 multi-cavity PET preform moulds per year, ranging from 8 to 72 cavities. The technology improvement and inheritance of Jinteng for many years have made the Preform Mould more durable, easier maintenance and more efficient production. Jinteng will serve you wholeheartedly and look forward to your down visit.