[A]:We have own standard mould frame for cap mould and handle mould, we make complete inspection on mould to ensure the structure consistence and spare parts standardized. In addition, we will do independent standardization test on mould cooling system and hot runner system.

- HUANGYAN JINTENG MOULD FACTORY

- Email Us: mail@jintengmould.com

Contact Us

- PET Preform Mould

- Cap mould

- Medical Consumables Mould

- Blow mould

- Commodity Mould

Choose Jinteng mould

to your needs

-

[Q]:Quality control of mould installation

-

[Q]:Product design and analysis

[A]:When we get samples or drawing of product, we always make all round analysis and inspection, such as moulding process feasibility, mould structure and movement feasibility, all the related plastic components matching situation, etc.

-

[Q]:Mould design and analysis

[A]:With precise analysis, foreseeing rationality analysis for mould design, best processing analysis and mould structure application, it offers the most professional solutions with the most suitable mould performance and technical specification as customer required. The analysis include mold-flow analysis, mould ejection, cooling system, rationality of guiding system, application of mould spare parts' specification, customers' machine selection and special requirement application, etc.

-

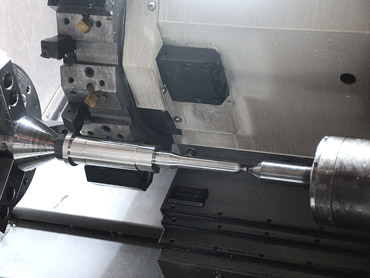

[Q]:Processing quality control

[A]:Control the size precisely, make self-inspection on each tooling spare parts in according to the requirements of drawing size and tolerance limits control. It is not allowed to make previous wrong workpiece inflow to the next tooling steps. All workpieces must be check up and control the precision by 3D coordinate measures. Self-inspection of tooling workpiece and acceptance check made by quality department;

-

[Q]:Acceptance inspection on T1 sample

[A]:We take full range test and analysis on product size, appearance, injection techniques and Physical Parameter. We use professinal inspection standard and tool for inspection. Along with our continuous improvement on equipments and measuring and test instruments, our product inspection tends to be more professional.

-

[Q]:Acceptance inspection on mould

[A]:To some extent, our mould testing aims at finding the quality problems of mould, while not cover the problems. Thus, we have many steps in mould testing, including dry running, high pressure bearing, high speed injection and necessary long time mould injection inspection.