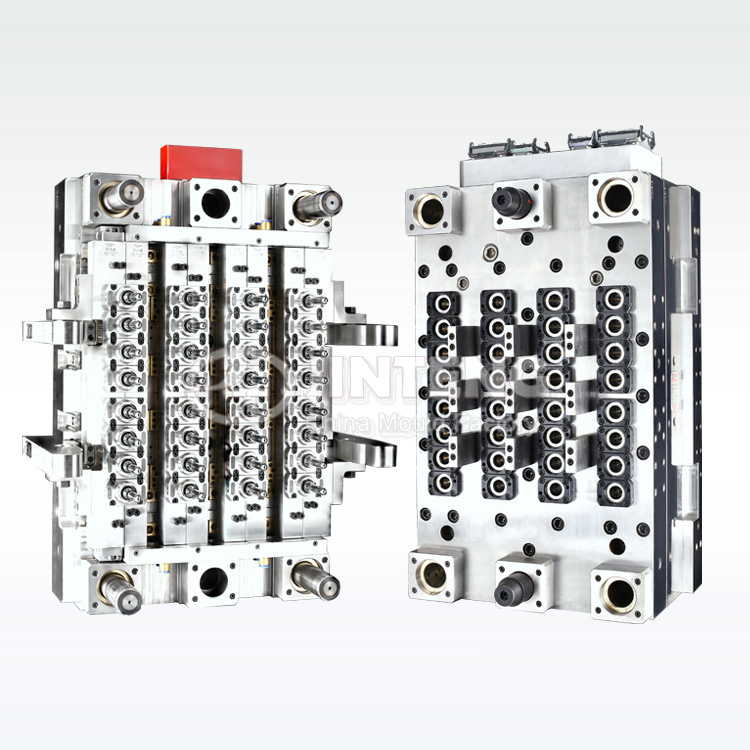

32 cavity hot runner PET preform mould with standard hardness for cavity and core, Germany steel for cavity and core, high speed injection, fully automatic ejection system, filter design in order to stop waste material come into the mould cavity.

Description:

Jinteng Molds is good at making all kinds of preform mould , 32 cavity hot runner PET preform mould is the PET preform mould we have done for our customers. After-sales Services: Experienced engineers will provide all-round technical solutions to any problems occurred in customers' mould operation.

Features:High efficiency, short delivery time, competitive price.

You may send your requirement, or 2D, 3D design to us, We can make kitchen ware mould exactly as your needs.