| PET PREFORM MOULD SPECIFICATION |

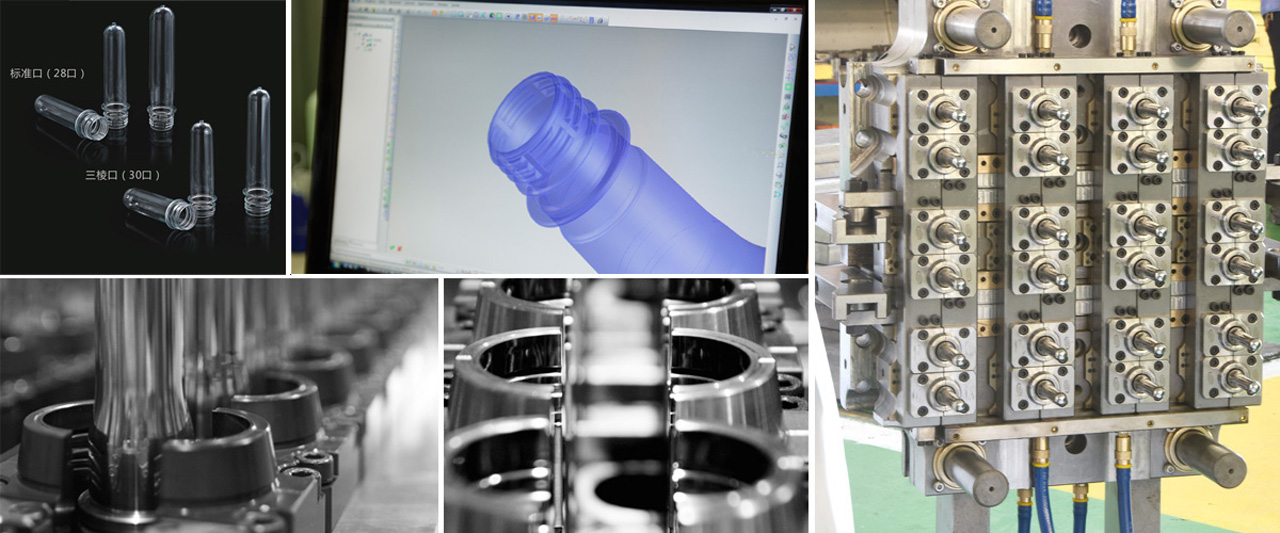

| Mould name | 72 cavity preform mould for 30/25 Neck 15.5g Preform |

| Mould cavity | 72 cavity |

| Neck finish | 30/25 Neck finish |

| Preform weight | 15.5g |

| Insert materials | 2316 stain steel from German |

| Mould body | #50 steel material |

| Cycle time | 28 sec with general PET screw type of injection molding machine |

| Cycle time with two stage injection system and Post cooling system | 14 sec with 3 stage post cooling system |

| Hot runner design | Balanced Hot runner with valve gate system |

| Suitable injection molding machines | Husky, Netstal PET line, PET Master, General PET injection molding machine |

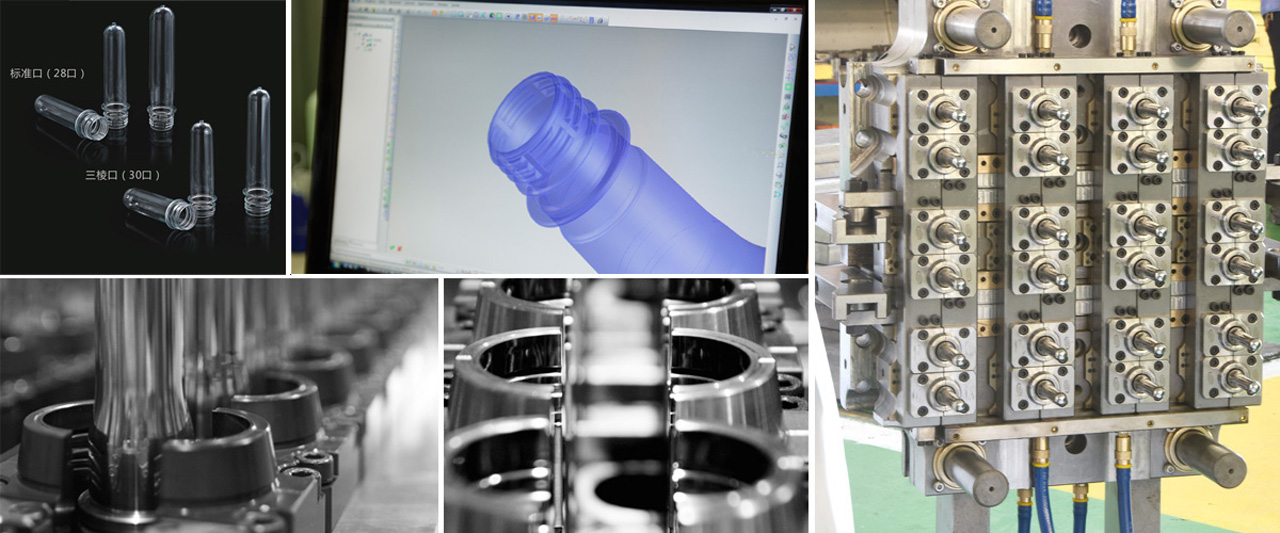

.We are one of the most reliable companies in this domain offering PET Preform Mould with advanced mould design technology.

Multicavity: 1-8 cavity, 12 cavity, 16 cavity, 24 cavity, 32 cavity, 48 cavity, 56 cavity, 72 cavity and 96 cavity.

Neck finish:PCO, 1810,1881,30/25,29/25,38 ,ALASK, ROPP; Jar neck and others.

PET preform Mould Feature

1. Mould plates are 4G13 or P20 stainless steel with pre-hardening process. Core, cavity and neck screw are made of S136 high Strength, anti-corrosive stainless steel. Mould plate is completed by one-time processing to ensure the concentricity of moulding hole and guide bush, guaranteeing the compact structure of mould.

2. Spiral cooling design for each single core and cavity, it helps to lessen the cycle time, improving production efficiency and saving costs. Opening/closing pulling plate adopts bearing slide type to drop the preform with realiable structure. And it is a highly integrated process of slider, pushing plate and ejection. All sliding parts surface inlaid self-lubricating copper alloys to ensure low friction effecient and strong wear-resistant.

3. Self- lock individually for each cavity to guarantee high precision and less defect of the final preform production as well as convenient disassembly.

4. Off-center adjustment system to ensure preform thickness difference < 0.10mm. Adopting double cone positioning principle guarantees high manufacturing precision to ensure the product without appearing flash, different size, irregular and other defects.

5. Experienced designers design preform mould with UG, Pro-E according to the clients sample; Preform thickness and height is reasonably and perfectly designed to ensure the final bottles weight light but feel hard.

6. Hot runner valve gate system is perfect used; No need to cut preform tail and it would save labor costs.

7. Hot runner system uses China advanced brand or imported hot runner system brand such as Yudo/Mastip/Hasco etc. Each cavity has independent temperature control and heater system. It will prevent the white defects on the preform and improve the qualtiy of plastic products.

8. Customer service: one year free warranty, life-long technical support service.

| Product Name | Multiple-cavity PET preform mould |

| Core &Cavity Steel | 2316#steel, S136 stainless steel or based on customer's requirement. |

| Mould base & Standard Component | DME,HASCO,MISUMI,LKM,Self-made with P20, 3CR13, 4CR13 material etc. |

| Steel hardness: | HRC30-35 for base material. |

| HRC45-48 for core and cavity material. |

| HRC60-62 for special parts material |

| Plastic material | PET, PP, etc. |

| Cavity Number | 1*4, 1*6, 1*8, 1*12, 1*16, 1*24, 1*32, 1*48 etc |

| Injection System | Pneumatic Valve gate with shut off&free-cut or short tail or long tail etc |

| Ejector System | Mould slider + Stripper plate ejection |

| Cycle Time | Based on PET preform thickness |

| Tooling lead time | 30-60 Days |

| Mould life | At least 2.0million Shots |

| Quality assurance | certificate for European customers |